ISO 8871-5

Ampoule Elastomeric Closure Testing

In the pharmaceutical industry, ensuring the integrity of packaging components such as elastomeric closures is critical to product safety and efficacy. ISO 8871-5 outlines the functional requirements and test methods for rubber stoppers used with parenteral containers, particularly vials and ampoules. This standard covers various test procedures including the penetrability test for rubber stoppers, ampoule leak test, like dye solution tightness test method, self-sealing testing method, and vacuum leak test method.

Understanding ISO 8871-5

ISO 8871-5 is part of a series focusing on elastomeric parts intended for pharmaceutical use. Part 5 specifically addresses the functional performance and integrity of closures that interface with injection systems. The objective is to ensure that closures allow penetration with reasonable force, reseal after puncture, and prevent contamination or leakage under stress conditions.

Penetrability Test for Rubber Stoppers

The penetrability test, defined in Annex A of ISO 8871-5, evaluates the force required to pierce an elastomeric closure using a hypodermic needle.

Principle

A closure is tested under standard conditions to measure the maximum force needed for a needle to penetrate it. Excessive penetration force may compromise usability and patient safety.

Test Procedure

- Secure the rubber stoppers onto vials with crimp seals.

- Equip a force-measuring device such as the Cell Instruments NPT-01 with a hypodermic needle.

- Pierce the stopper perpendicularly.

- Record the peak force required.

- Repeat with new needles on additional samples (10 total).

Significance

This test simulates the real-world use of multi-dose vials and ensures ease of administration while maintaining sterility.

Ampoule Vacuum Leak Testing

Self-Sealing and Dye Solution Tightness Test

Annex C of ISO 8871-5 outlines a combined self-sealing testing and dye solution tightness test after repeated punctures.

Principle

The test checks the ability of a stopper to reseal after multiple penetrations and resist leakage when subjected to vacuum-induced pressure differentials.

Test Procedure

- Fill 10 clean vials with particle-free water to nominal volume.

- Seal with the test closures and crimp.

- Pierce each closure 10 times using a new needle each time.

- Submerge the vials in methylene blue dye solution.

- Apply vacuum (−27 kPa) for 10 minutes, then return to atmospheric pressure.

- Let sit for an additional 30 minutes, then rinse and inspect.

- Any blue coloration inside the vial indicates seal failure.

Ampoule Leak Test Using Dye Solution (Annex D)

This test specifically assesses the closure/vial interface integrity under stress conditions without prior punctures.

Procedure Summary

- Fill, seal, and cap the vials.

- Immerse them in methylene blue dye.

- Apply vacuum and maintain as per the protocol.

- Inspect for dye ingress post-immersion.

- Dye presence inside indicates a leak.

This test is critical for ampoule leak test protocols where closures must maintain sterility even under transportation or storage stress.

Why These Tests Matter

- Patient Safety: Prevents contamination and dosage variability.

- Regulatory Compliance: Satisfies stringent pharmaceutical QA requirements.

- Product Integrity: Maintains shelf-life and therapeutic effectiveness.

By performing the penetrability test for rubber stoppers, self-sealing testing, and ampoule leak test, manufacturers uphold standards for parenteral packaging systems as mandated in ISO 8871-5.

Recommended Instruments from Cell Instruments

To ensure precise and repeatable testing, Cell Instruments offers advanced, compliant testing solutions:

NPT-01 Penetrability Tester

Optimized for penetration force analysis of elastomeric closures.

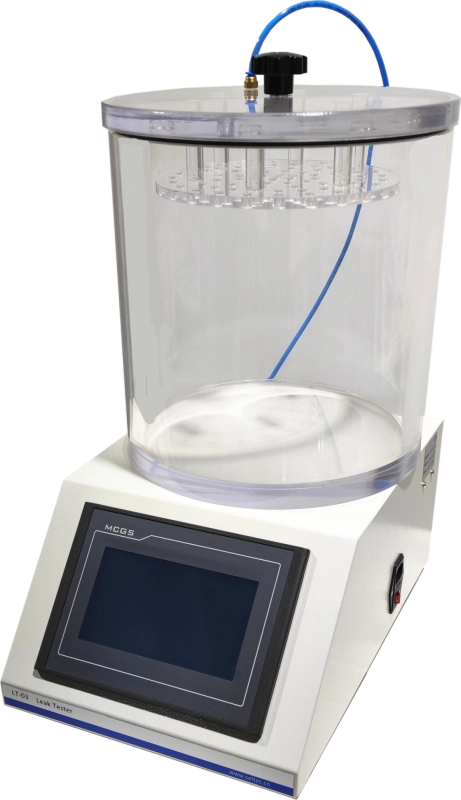

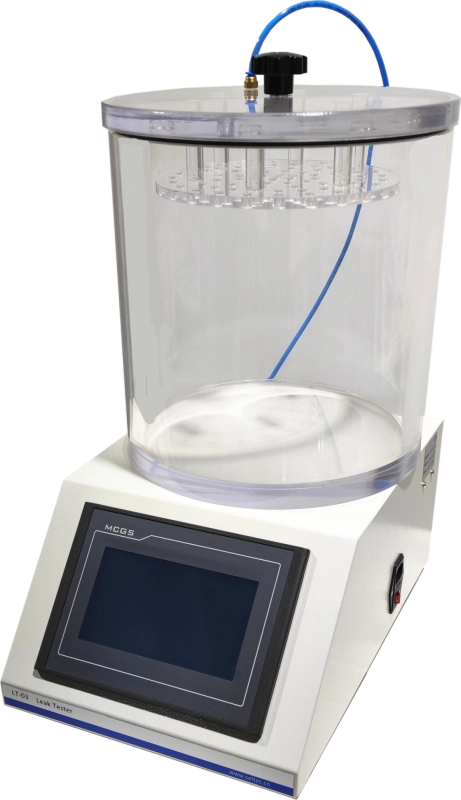

LT-03 Vacuum Leak Tester

Ideal for performing vacuum-assisted dye penetration test.