Ampoule Leak Test and the Role of the Ampoule Leak Testing Machine

Sissejuhatus

Ampoule leak testing is a critical procedure used to ensure the integrity of ampoules, which are sealed containers used for storing pharmaceuticals, vaccines, and other sensitive materials. These glass containers must remain airtight to protect their contents from contamination, oxidation, and degradation. The ampoule leak test helps verify that the ampoules meet industry standards for safety and reliability.

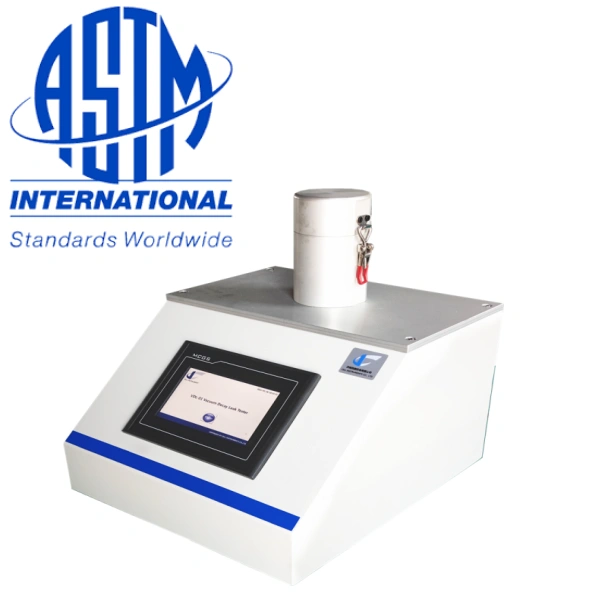

In this article, we will delve into the importance of ampoule leak testing, the role of the ampulli lekkekatse masin, and how the vacuum decay leak test—outlined in the ASTM F2338 standard—is used for detecting leaks in ampoules. This method provides a nondestructive ja accurate way to ensure that ampoules maintain their integrity throughout storage and transportation.

Understanding the ASTM F2338 Standard for Nondestructive Leak Testing

The ASTM F2338 standard defines the test method for nondestructive detection of leaks in packages—including ampoules—by the vacuum decay method. This test is essential for identifying micro leaks or any small imperfections that could compromise the sterility or safety of the contents of the ampoule.

The test method works by placing the ampoule in a sealed test chamber, applying a vacuum, and then measuring the decay in pressure over time. A change in pressure indicates that air is escaping through a potential leak in the ampoule, allowing for the identification of compromised ampoules without causing any damage to them.

The vacuum decay leak test is a highly sensitive technique. It is especially effective for testing ampoules because it can detect even the smallest leaks, which are often invisible to the naked eye. The results are typically shown through a pass/fail indicator, and ampoules that fail the test are flagged for further inspection or disposal.

How the Ampoule Leak Testing Machine Works

The ampulli lekkekatse masin is designed to perform the vacuum decay leak test automatically. This machine is equipped with advanced features, such as sensitive pressure transducers and precise vacuum control systems, to ensure accurate leak detection. Here’s how the process works:

- Setup: The ampoule is placed inside the testing chamber, which is then sealed. The chamber is equipped with pressure sensors to measure any changes in pressure.

- Vaakumrakendus: The chamber is evacuated to create a vacuum. This process simulates the conditions that the ampoule will experience during storage or transport.

- Rõhu jälgimine: Once the vacuum is applied, the machine monitors the pressure decay inside the chamber. If the ampoule is intact and sealed properly, the pressure should remain stable. Any pressure drop indicates a leak in the ampoule.

- Lekke tuvastamine: The machine calculates the pressure change over time. A large leak will cause a significant drop in pressure, while a smaller leak will show a slower decline. The vacuum decay leak test is highly sensitive and can detect even the tiniest imperfections.

- Test Results: Based on the rate of pressure decay, the machine determines whether the ampoule passes or fails the test. If a leak is detected, the ampoule is flagged for further inspection.

Advantages of Ampoule Leak Testing

The ampoule leak test offers several advantages for manufacturers and quality control teams in the pharmaceutical industry:

- Nondestructive Testing: Unlike some other testing methods that may damage the product, the vacuum decay leak test is nondestructive. This ensures that the ampoule can still be used after testing if it passes the leak test.

- Kõrge tundlikkus: The method is highly sensitive and can detect even microscopic leaks. This is crucial for ampoules, which need to maintain a perfect seal to ensure the safety and efficacy of the product inside.

- Fast and Efficient: The ampulli lekkekatse masin provides quick results, allowing manufacturers to test large batches of ampoules in a short amount of time. This efficiency is critical in maintaining high production standards.

- Improved Quality Control: By using an ampulli lekkekatse masin, manufacturers can ensure that all ampoules are free from leaks, reducing the risk of contamination and ensuring the integrity of the pharmaceutical products.

Applications of Ampoule Leak Testing in the Pharmaceutical Industry

In the pharmaceutical industry, ensuring the integrity of ampoules is essential for product safety. The vacuum decay leak test, as defined by ASTM F2338, is commonly used to:

- Test Sterility: Ampoules containing vaccines, injectables, or sterile solutions must be leak-free to prevent contamination. Any breach in the seal can compromise the sterility of the product.

- Prevent Oxidation: Some pharmaceutical products are sensitive to oxygen and must be stored in airtight containers to preserve their effectiveness. Leaks can allow oxygen to enter, causing degradation of the product.

- Ensure Safety: If an ampoule leaks during transportation or storage, it could cause dangerous contamination. The ampoule leak test ensures that only intact products reach consumers, ensuring public safety.

- Compliance with Regulatory Standards: Many regulatory bodies require leak testing to ensure that pharmaceutical packaging meets safety standards. The vacuum decay leak test provides reliable, reproducible results that help manufacturers meet these requirements.

Kokkuvõte

Ampoule leak testing is a critical process in ensuring the safety, sterility, and efficacy of pharmaceutical products. By using an ampulli lekkekatse masin and adhering to standards like ASTM F2338, manufacturers can accurately detect leaks, ensuring that only high-quality, intact ampoules reach the market.

For companies looking to streamline their leak testing processes and meet industry standards, the Cell Instruments Ampulli lekke tester offers a reliable solution. With its vacuum decay leak testing capabilities, it helps manufacturers ensure that their products meet the stringent requirements for safety and quality.